Requirement

A poultry processing company from Europe approached us as part of a modernisation project in the receiving area. The aim was to integrate a gross tare weighing system in order to record the quantities delivered more accurately and at the same time achieve an increase in efficiency.

Solution

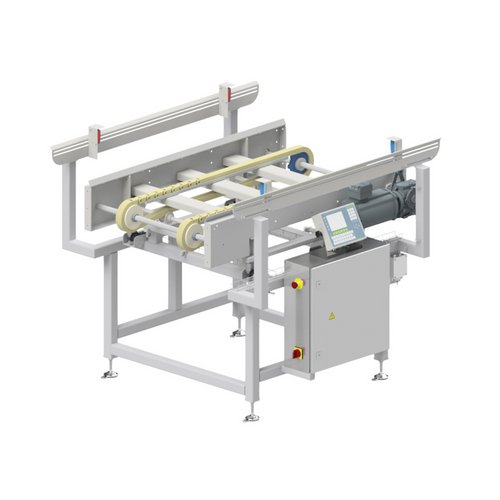

To solve our customer's problem, two catchweighers were integrated into the incoming goods conveyor line. These record the weights of the full crates and thus the gross weights. In order to realise the desired throughput, three full crates are always conveyed to the scales at the same time. There, the weight is determined, continuously added up with reference to the current batch and transferred to the higher-level control system before the crates are transported away.

During further processing, the crates are emptied before they are fed to another catchweigher, which acts as a tare weigher. This records the specific tare weight for each individual crate. In combination with the previously determined gross weights, this makes it possible to determine the exact quantities delivered and subsequently determine the efficiency of processing.

As there are high hygiene requirements in the entire goods receiving area, all three scales were designed to be easy to clean, with as few horizontal surfaces as possible and good accessibility.

The most important added values:

- Customised development for seamless integration into the conveyor system

- Recording of specific tare weights subject to verification despite varying crate weights

- Software-based communication between the scales to synchronise the weights

- Real-time data transfer to the customer's control system

Sascha Wolff

Technical Product & Business

Development Manager

Phone: +49 5401 4977 41

Mobile: +49 160 90593515

s.wolff(at)hoefelmeyer.de