The future of production: 0 errors with maximum product quality. The use of IRIS is the initial step in making your production future-proof. – a modular software for quality assurance. Data that should be together are brought together.

Software that revolutionises your quality management: IRIS

Do you have any questions about IRIS? I will be happy to answer these and show you what advantages the use of IRIS will have for your company.

Intelligent and innovative quality management

Take your production and quality management to the next level. The IRIS Weighing Control quality management software will support you in this. It brings together relevant production data in a fully automated way and allows you a detailed real-time analysis of quality management. This enables you to digitise your production step-by-step, link machines in a network and record data from different scales. Fully automatically – without transmission errors due to humans.

Jan Haferland

Strategic product & business

development manager

Phone: +49 5401 4977 34

Mobile: +49 179 2933562

j.haferland(at)hoefelmeyer.de

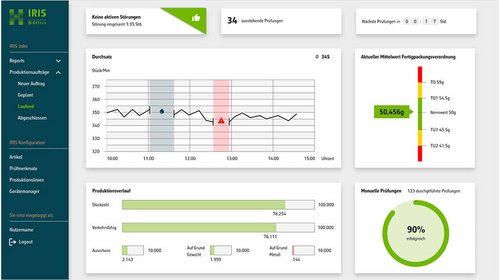

Multifunctional quality parameters

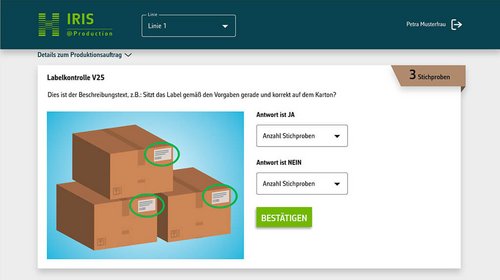

Not only weight data is recorded and checked, but also other parameters that can be set individually such as optics, taste, temperature, texture.

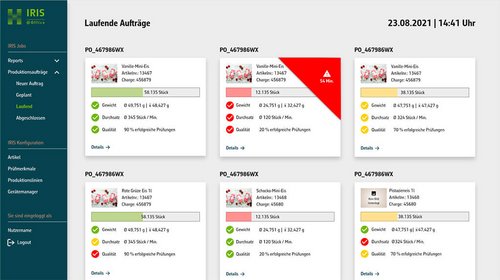

Real-time information at all terminals

Retrieve all data in real time and not only when the batch has run through: detect deviations immediately and take appropriate action straight away. You don't have to sit at the PC anymore – even with a tablet or smartphone, you are always informed about all processes in your production, regardless of the device.

Cloud or On Premise

IRIS can be implemented at your plant as a Cloud solution or On Premise solution - your IT security concept decides:

Intuitive user guidance

IRIS is so intuitive and easy to operate that you and your employees will not need any long periods of training and can thus immediately benefit from all its advantages.

Future-proof

Thanks to the continual further development and related updates, we ensure that IRIS is always up-to-date and receives new features, thus protecting your investment.

Development in Customer Co-Creation

We developed IRIS Weighing Control together with a selected group of customers from the food industry, pharmaceutical industry and other branches in order to ensure that the software is optimally matched to your requirements.

Networked machines

IRIS connects the data from your machines. Process station, hygienic scales, drive-through scale or external products. Thanks to networked machines, you have all the relevant data for your statistical quality assurance in one place.

Improved production

What is improved by IRIS? Quite simply the entire production process. Illegible data sheets, which are often a reality with handwritten documentation under stress, become a thing of the past. Automated data transmission by the software reduces work steps as well as human transcription errors and improves your quality assurance.

The advantages of IRIS at a glance:

Additional benefits for your company

If you use the IRIS software in your quality management, it will have a positive effect on both the production and the entire company. Your company will become more sustainable because it is paperless. You have control over legal requirements, especially in the area of the Pre-packaging regulation(FertigPackV) for food. And you check the qualitative aspects of your products at the same time and can directly view them .

IRIS thus takes the digitisation and quality management of your FertigPackV to a new level – more integrative, smarter, more profitable and easier than ever before.

You are welcome to test what IRIS can do in advance. Get in touch with us and we will show you how you can improve your production.