X-ray inspection systems v complete your quality control. They inspect your products according to internal and external quality specifications and detect unwanted contaminants in your products. This includes metallic and non-metallic foreign bodies such as glass, stones, bones and plastics - regardless of the packaging.

X-ray inspection: foreign body-free products

An X-ray system in your company's quality assurance process protects customers and consumers from foreign bodies in products and you from reputational damage. This increases customer satisfaction, protects you from risks and safeguards your reputation. As an end-of-line application, our X-ray scanner guarantees optimum product security and detects even the smallest contaminants - regardless of the type of product packaging. X-ray inspection filmssystems even detect in cans or metallised the smallest foreign objects.

The system consists of the following main components:

A X-ray tube: This is where the X-rays are generated electrically. It exits through a narrow slit in the tube and penetrates the product to be analysed from bottom to top as a fan-shaped beam.

B X-ray beam

C Transport system: A PE flat belt (self-guiding) transports the product to be analysed evenly through the X-ray beam. This makes it possible to scan the product line by line.

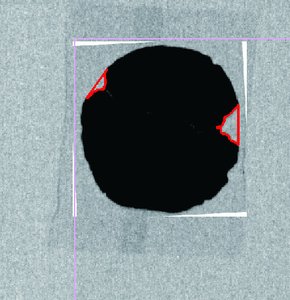

D Detector unit: The linear detector, which is installed above the inspection opening, converts the incoming X-rays into an electrical signal from which a digital X-ray image is created.

E Industrial PC: This is where the image is analysed and the reject systems are precisely controlled.

Applications for X-ray inspection

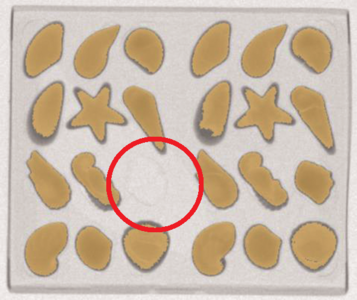

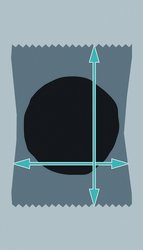

X-ray inspection systems are versatile in their use. They not only check whether there are foreign objects in your product, but also the qualitative characteristics of your products. For example, completeness, shape, integrity (breakage), dimensions, weight and even the integrity of sealed seams can be checked.

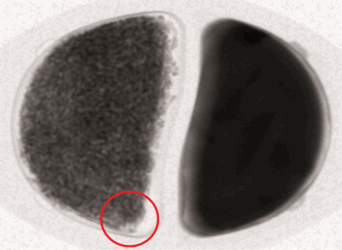

Precise detector resolution

The extremely fine resolution, which reaches down to a maximum of 0.1 mm, recognises the smallest impurities made of metal, glass, ceramic, stone and sometimes even plastic. The X-ray system recognises even tiny product defects such as cracks or even air pockets.

Seamless data acquisition

Data collected by the X-ray system can be transferred directly to our software solutions. This allows you to keep an eye on your current production in real time.

Rejection units for rejected products

If a foreign object is detected or a product is faulty due to quality characteristics, separation systems such as pushers, blow nozzles, diverters or hinged belts eject the affected products directly.

Foreign body control and other attributes

In addition to checking for contamination, the X-ray scanner recognises other product attributes such as completeness, breakage, position and filling quantity.

Artificial intelligence

The X-ray system also allows the use of artificial intelligence. Captured data can be used to train a model, which means that even difficult applications such as recognising olive pits can be implemented.

Single or multi-track operation

Our X-ray system offers maximum flexibility for your company. You can work in classic single-track operation or inspect several products in parallel in multi-track operation - of course with true-to-lane ejection.

Easy to clean and maintain

The design of the X-ray systems allows quick and easy cleaning processes. All components are also easily accessible and easy to replace during maintenance.

Download

Find out how industrial X-ray systems guarantee product safety

I will be happy to clarify any questions about X-raying in the industry so that you always bring products to market that meet your quality guidelines.

Sascha Wolff

Technical Product & Business

Development Manager

Phone: +49 5401 4977 41

Mobile: +49 160 90593515

s.wolff(at)hoefelmeyer.de

The added value of the X-ray system:

The X-ray scanner offers your company reliable foreign object detection, maximising product safety and protecting your company from product recalls and serious reputational damage. The 100 per cent inline inspection detects defects immediately, documents them and ejects the relevant products directly.

Further advantages:

High detection accuracy

Thanks to their high detection sensitivity, our X-ray systems recognise a wide variety of foreign objects - metallic and non-metallic, including glass, stone, ceramics and certain plastics.

Flexible and customisable

Thanks to the wide range of application options, the X-ray system adapts to your production process and supports you in realising your quality assurance.

Detection of low-density contamination

After the X-ray system has been trained with product images, it finds low-density contaminants such as fish bones, chicken bones and other difficult-to-detect contaminants with high accuracy and extremely low false reject rates.

Wide range of applications

Thanks to the hygienic stainless steel design and protection ratings of IP54 | IP66 | IP69, the systems are suitable for any production environment.

Easy to maintain and durable

The modular assemblies allow uncomplicated maintenance work, increase the service life and also have a positive effect on operating times.

Foreign body detection and optimised production processes

High-quality products require precise weighing technology, foreign object detection, efficient processes and a holistic view of production. We are the right partner for optimising your processes at all times. From the millimetre-precise integration of our product inspection systems to services such as maintenance or holistic production optimisation: Put your trust in Höfelmeyer.

Services for you:

![[Translate to Englisch:] Röntgeninspektionssysteme [Translate to Englisch:] Röntgeninspektionssysteme](/fileadmin/_processed_/f/8/csm_Roentgenscanner_Basic_4de1280a4a.jpg)