First-class product quality, satisfied customers and an impeccable reputation: Inspection systems automatically check your goods for compliance with required product specifications, contamination by foreign bodies and thus ensure that your products always meet internal and external quality standards.

Checkweighers, metal detectors or X-ray systems check the quality of your products and enable the early rejection of products with incorrect weights or contaminated with foreign bodies.

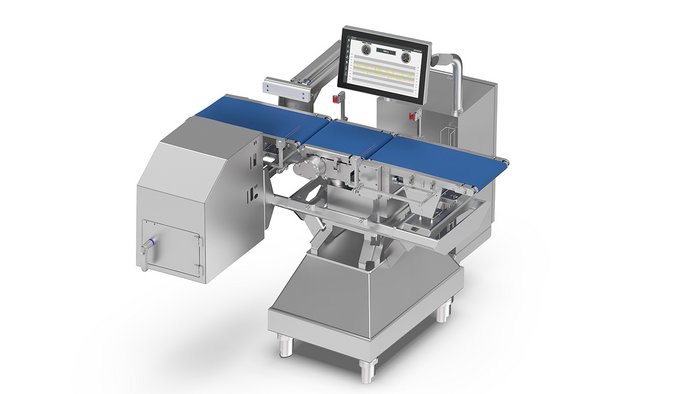

![[Translate to Englisch:] Röntgensystem [Translate to Englisch:] Röntgensystem](/fileadmin/_processed_/f/8/csm_Roentgenscanner_Basic_67d4aecd2d.jpg)

X-ray system

Inspection of up to four products simultaneously for foreign objects and quality features such as completeness, weight, intactness and position.

Seamless weight control

With the dynamic checkweighers, you can check 100% of your products within your production line for compliance with the nominal filling quantity and automatically sort out incorrectly weighed items.

Seal seam inspection

Seal inspection checks the integrity and leak-tightness of packaging, preventing products with damaged packaging from being sold.

Foreign body detection

Foreign object detection increases product safety and detects unwanted objects such as metal, glass or plastic in the products.

The use of inspection systems with the appropriate software is advantageous throughout the entire value chain, from incoming goods to production and outgoing goods. This allows you to check the quality of raw materials, have an overview of whether everything is running according to plan in production and be sure that your customers receive correctly filled, foreign body-free and undamaged products.

Consumer protection

Inspection systems such as metal detectors or X-ray scanners protect consumers from health risks caused by foreign bodies, ensure product quality and protect your company's reputation. from foreign bodies and ensure consistent product quality.

Customer satisfaction

The use of different product inspection systems ensures that your customers and end consumers receive products of the desired quality. This increases customer satisfaction and brand loyalty and leads to long-term market expansion.

Compliance with external requirements

There are many specifications, especially in the food sector. Inspection systems such as X-ray scanners or metal detectors are reliable tools that support you in complying with these specifications and requirements.

Image protection

If products containing foreign bodies are placed on the market, this often has serious consequences for your reputation. Product recalls result in high economic costs and can damage your company's image in the long term.

Do you have any questions about the different testing systems and their areas of application? I would be happy to clarify these in a discussion.

Sascha Wolff

Technical Product & Business

Development Manager

Phone: +49 5401 4977 41

Mobile: +49 160 90593515

s.wolff(at)hoefelmeyer.de

Our aim is to ensure that your product quality is maintained. In addition to customised inspection systems, we take a holistic view of your company and offer you exactly the solutions you need. From different scales to quality assurance software.

![[Translate to Englisch:] Förderbandsystem [Translate to Englisch:] Förderbandsystem](/fileadmin/_processed_/0/2/csm_Metalldetektor_aa5230f054.jpg)

![[Translate to Englisch:] Inline-Metallseparator [Translate to Englisch:] Inline-Metallseparator](/fileadmin/_processed_/f/d/csm_Retuschiert_227517f3b8.jpg)

![[Translate to Englisch:] Rohrmagnetseparator [Translate to Englisch:] Rohrmagnetseparator](/fileadmin/_processed_/5/5/csm_Rohrmagent_Separator_3379f5963b.jpg)